Lightweight, modular drive-train design optimized for offshore wind turbines

OptiGen's drive-train design has the potential to boost the competitivity of the wind power industry. It allows to achieve a drastic reduction in the weight of wind turbine generators, as well as their construction, maintenance and repair costs. As a result, OptiGen significantly reduces LCOE and associated CO2 emissions. Although originally designed with floating offshore applications in mind, the OptiGen drive-train design has potential for a broad range of aplications across all wind power segments.

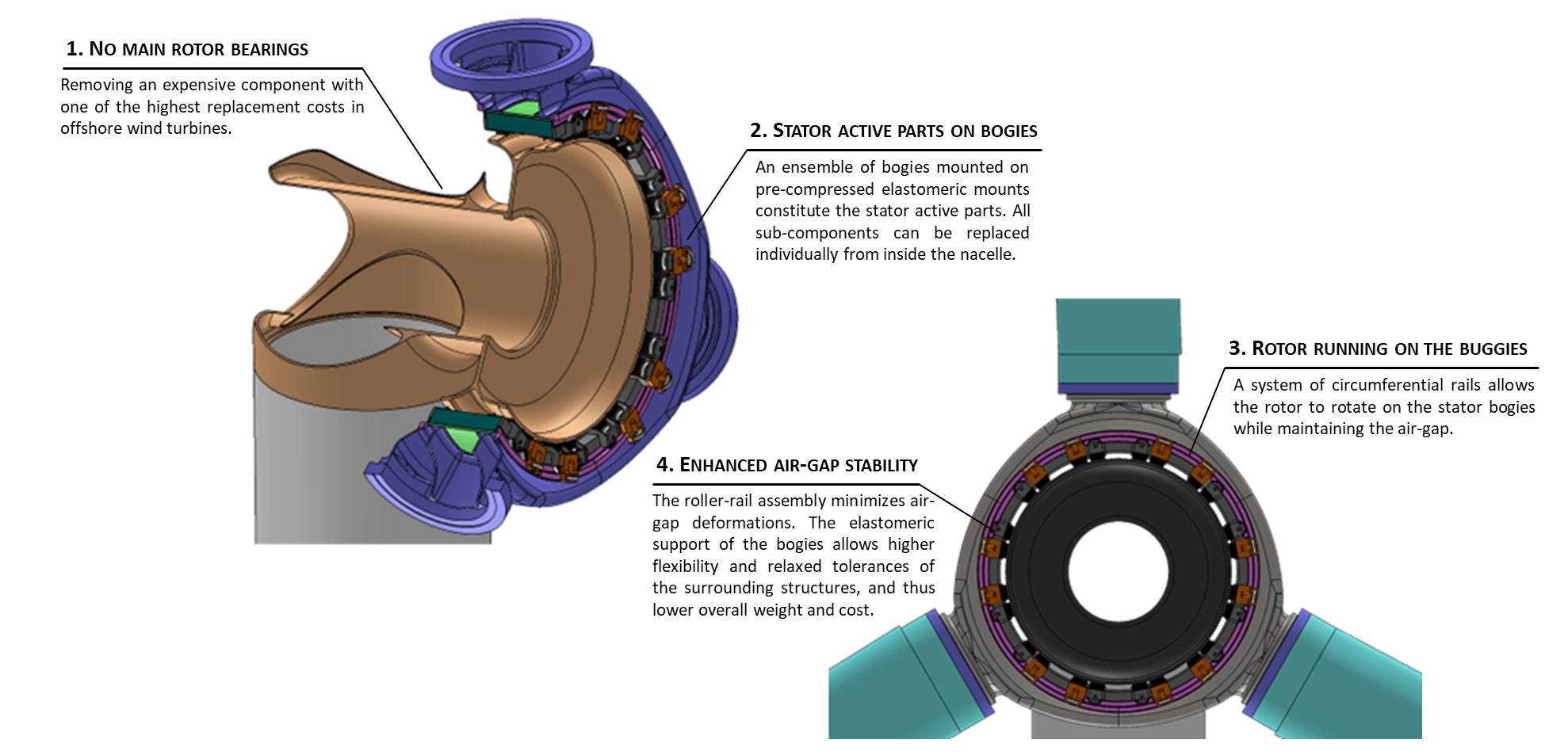

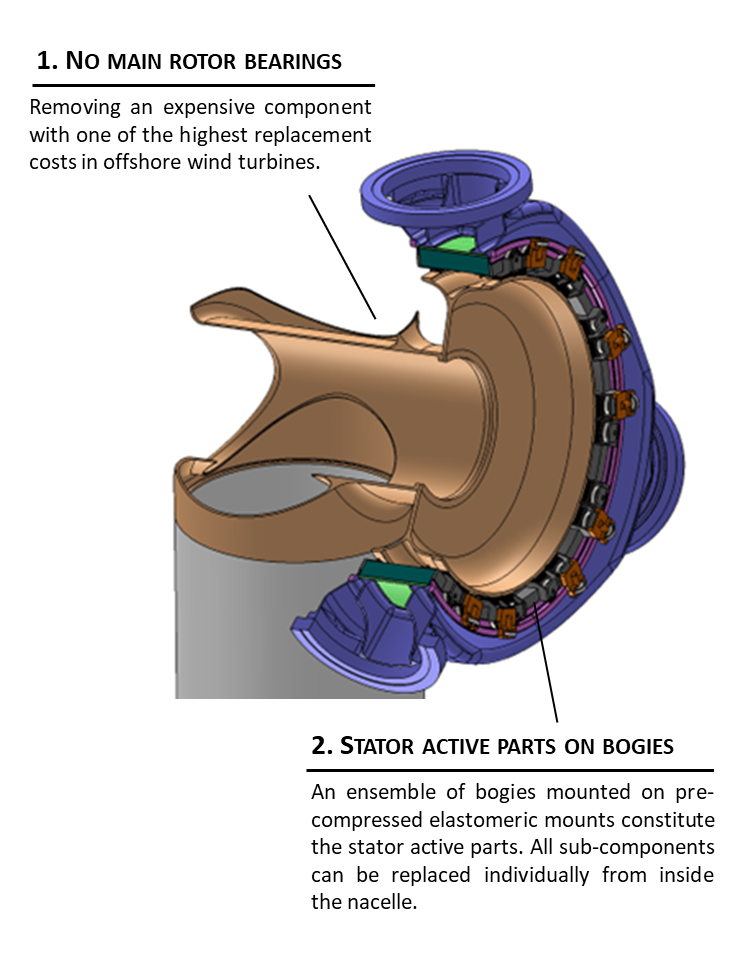

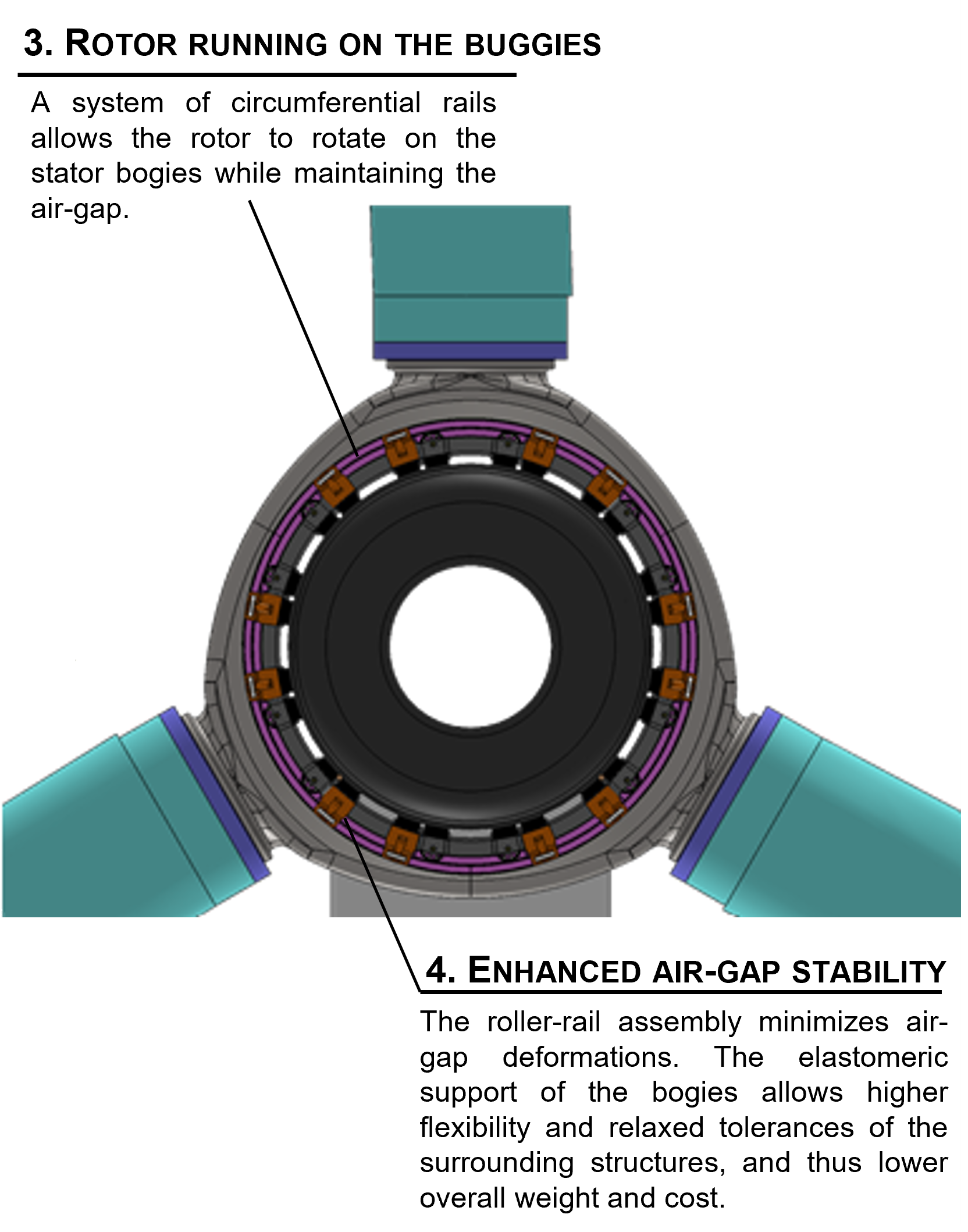

Key features

The system achieves at least a ~30% reduction in drive-train weight, leading to significant cost reduction, also of downstream components like the yaw system, tower, substructure and foundation.

The OptiGen design results in very high air-gap stability. This allows for a reduced air-gap length and thus further savings in active materials.

The air-gap stability is not only improved, but it also becomes much less dependent on air-gap diameter. This makes direct-drive generator designs more easily scalable and improves their competitivity at high power ratings.

The modularity of our design allows for simpler assembly, maintenance and repair, without the need of heavy-lift cranes, jack-up vessels, or towing to port in case of floating wind turbines.

The OptiGen design allows to manufacture stator and rotor structures in segments with lower tolerance requirements. This increases the supplier panel, potentially also including local suppliers.

As the mechanical components like bearings and rollers can be easily exchanged, the OptiGen design allows for a significant extension of turbine service life or even power upgrades.

Achieving a lower LCOE

Floating offshore wind has great potential to add to the renewable energy production capacity worldwide, but it also has the highest Levelised Cost of Energy (LCOE) among renewable sources of energy, at levels above 100 €/MWh. To be competitive, offshore wind will have to drastically reduce its associated LCOE to levels closer to ~60 €/MWh.

The OptiGen drive-train design can significantly contribute to achieve this goal and position floating offshore wind power at the forefront of energy sources by the end of the decade.

If you want more information, feel free to send us an e-mail on info@optigen.org, or contact us using the following form: